--- A kind of mature precleaner had been used widely.

--- Suitable in many applications and works well in harsh and heavy dust environment.

Especial in farm equipment & mining equipment.

--- Cost savings on filter elements.

--- Servicing could be done anywhere and spares are not needed.

--- Longer service intervals.

How it Works

1.Contaminated air is drawn through the inlet in the center of the unit towards the oil pan below.

2.Heavier and larger dust particles are trapped in the oil pool at the base of the unit.

3.Lighter and smaller particles are further trapped by the filtration mesh which is wetted by

oil droplets as the air travels upwards through the mesh.

4.Only purified air enters the air cleaner or engine.

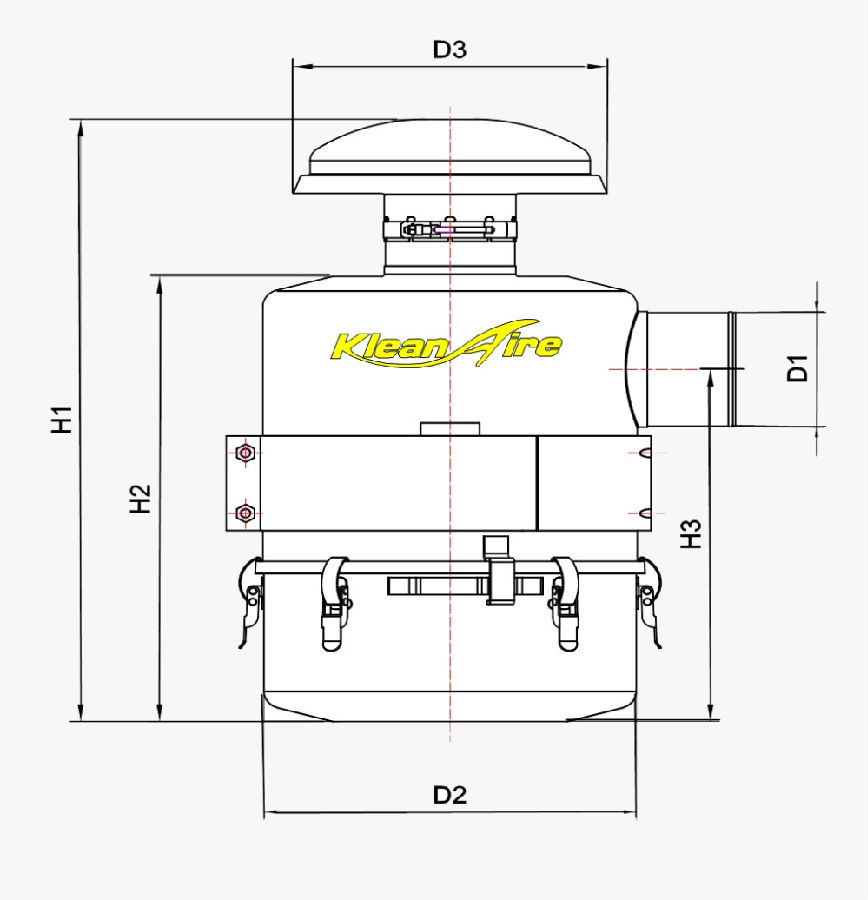

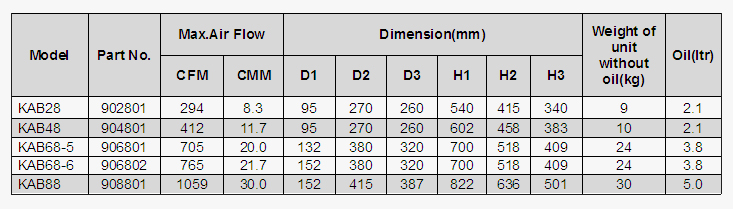

Technical Specifications

---KAB28/KAB48/KAB68/KAB88

General Instructions

1.Select the appropriate oil bath model as per the engine’s airflow requirement.

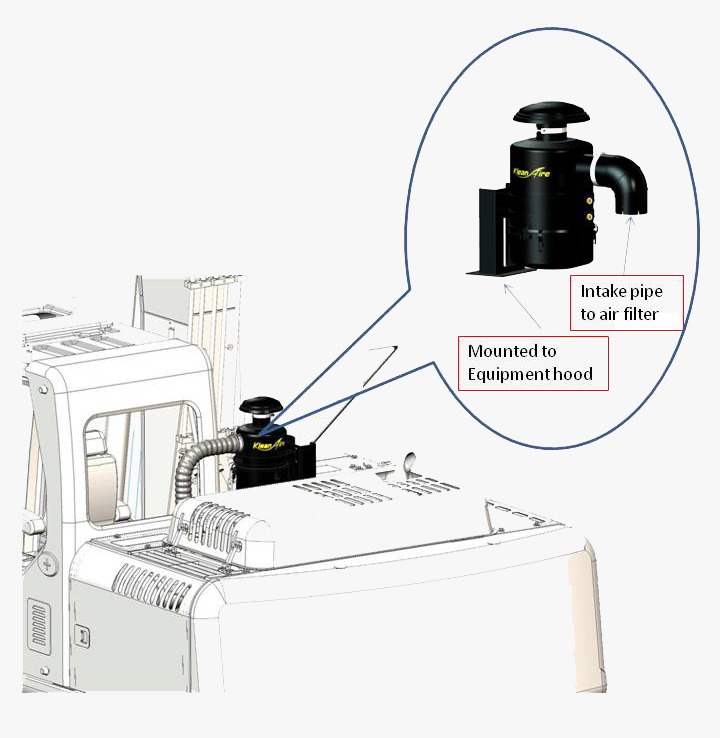

2. It must only be installed in a vertical position.

3.The oil bath aircleaner must not be mounted flush against any surface of the

equipment as disassembly is needed for clearance and replacement.

A minimum of 50mm (H) is recommended.

4.Ensure sufficient space clearance at the base for access and removal of the oil

pan during servicing.

Servicing Instructions

1.Allow ten minutes after turning off engine for oil to settle in the pan.

2.Release the fastening clips, remove the lower casing and dispose the oil and sludge in an appropriate manner.

3.Remove the lower mesh and clean with diesel fuel or kerosene.Immersion of the whole mesh component in diesel

oil or kerosene is recommended for best cleaning results.

4.Drip dry or blow dry the mesh with compressed air before re-assembling the unit.

5.Fill the pan with engine oil up to the marking level indicated.

6.Ensure all fastening clips are secured.

7.SAE Grade 10 oil is recommended for sub zero temperature and SAE Grade 30 for all other temperatures.

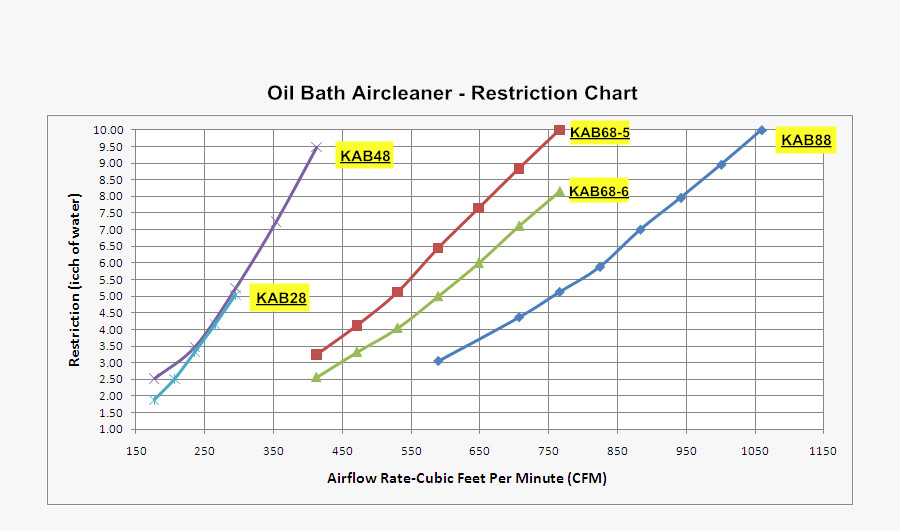

Performance Chart